| Machine height (mm) | 1500 mm |

| Machine width (mm) | 2100 mm |

| Machine length (mm) | 2300 mm |

| Empty weight (kg) | 600 kg |

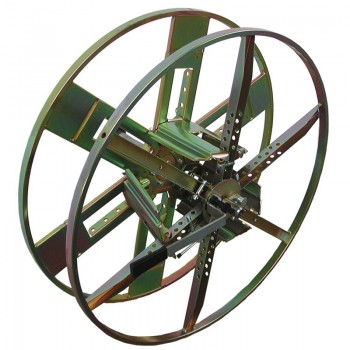

| Drums - maximum diameter (mm) | 1250 mm |

| Drums - minimum diameter (mm) | 600 mm |

| Drums - Maximum width (mm) | 810 mm |

| Drums - Minimum width (mm) | 300 mm |

| Drums- Max. weight capacity (kg) | 1300 Kg |

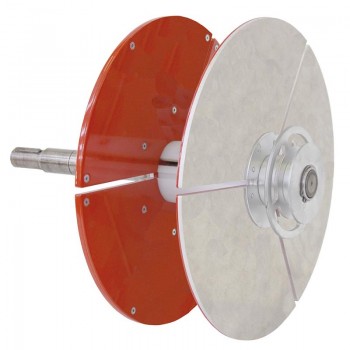

| Coils - max. internal core diameter (mm) | 620 mm |

Item no. BOB-MAT-MF-U12-MP MEDIUM PERFORMANCE - 20-30 operations a day on average

BOB-MAT-MF-U12/SP08-00/OA10Q60/NE-218/OE-B-10

Technical data sheet

| Coils - min. internal core diameter (mm) | 320 mm |

| Coils - maximum width (mm) | 220 mm |

| Coils - minimum width (mm) | 115 mm |

| Coils - max. diameter (mm) | 950 mm |

| Max. coil weight | 250 kg |

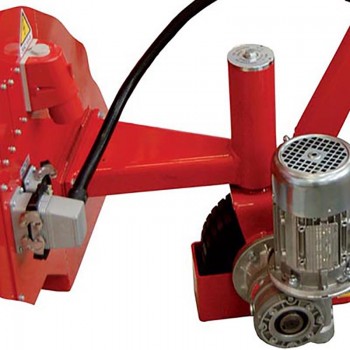

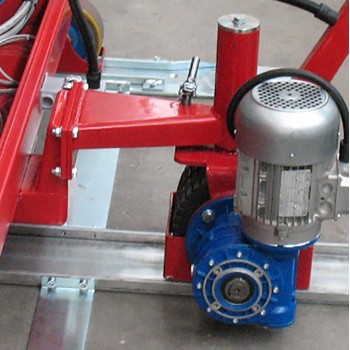

| Total power (kW) | 1,5 KW |

| Torque | 274 Nm |

| Machine movement speed | 4 Km/h |

| Min./max. rpm (rpm at drum) | 0-70 g/min |

Accessories included

Accessories on request

Item no. OA/10Q60/OM/MID-SN

Electronic precision counter with display

MID EUROPEAN TYPE APPROVAL

ADD TO QUOTE

DETAILS

Item no. ERCA-LV

FOR MOVING THE UNIT WHEN EMPTY

Select front or side fitting (see accessories)

ADD TO QUOTE

DETAILS

Item no. ERCA-PC

FOR MOVING THE UNIT WHEN LOADED

Select front or side fitting (see accessories)

ADD TO QUOTE

DETAILS

Item no. BA-BOB/24/180

Battery-powered power supply for running machines fully independent from 220-380V mains

ADD TO QUOTE

DETAILS